Mosaic classes are listed here by geographic area with links to the artists and organizations offering the classes.

Mosaic Art Supply, LLC, makes no recommendation or guarantee for any of these classes. Looking at the instructor’s artwork can be a good way to tell if their class is for you. If you teach mosaic classes and would like to be added to this directory, please apply by sending an email to us: [email protected]

Still having trouble finding a mosaic class in your city? Visit our page for how to find mosaic classes in your local area.

Classes Within the U.S.A.

ARKANSAS

[email protected]

Mosaic Maddess offers classes throughout the state of Arkansas in conjunction with Spread Your Wings Mosaics. These “Mobile Madness” classes can be ongoing (weekly or monthly), or a one-time project. Classes are tailored to the participants, and range in difficulty accordingly. 501-321-1110

CALIFORNIA

www.kimemersonmosaics.com

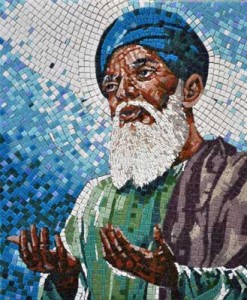

The mission at the San Diego Mosaic School is to educate and inspire everyone about the medium of mosaics as a fine art. Every level of mosaic experience is welcome. All you need is a passion for color, texture, an openness for creativity, and originality. We focus on cutting, placement of “tesserae”, compositional design, and comparing ancient Roman mosaics to the contemporary while using many different types of beautiful materials. We are located in the Normal Heights community of San Diego, California, USA.

www.katherineengland.com

Katherine has classes for beginners and more advanced students covering basic mosaic techniques, mosaic garden sculptures, soldering stained glass, and fused glass. She also offers drawing and painting instruction.

www.paintedchairstudio.com

Nancy has been teaching mosaics at her studio in Santa Cruz, Ca for the past 20 years. She offers a variety of mosaic classes that include working in tiles, plates, ceramics, stained and fused glass. They are designed not only for beginners but also mastering more complicated sculptural projects. Nancy also makes a line of ceramic pieces that can be included in the mosaic projects. The large indoor studio and garden provide a relaxing and creative space, just a few blocks from the beaches in Santa Cruz.

www.growbetterveggies.com

The Love Apple Farms Educational Center offers classes for making a pique assiette garden stepping stone from your own broken china, crockery, tile, etc. Advance registration is required. Classes are held rain or shine.

www.mkmosaics.com

Mosaics are making a comeback as artists all over the world are rediscovering ancient techniques and stretching those to new and modern expressions. I invite you to explore this timeless art-form by studying classical principles and techniques handed down through the centuries by mosaic masters. From these ancient core techniques the student/artist develops a solid, yet ever-expanding knowledge from which to move forward into more contemporary applications if they choose. I hope to welcome you to one of my classes or workshops in this marvelous and meticulous art-form.

www.santabarbaraschoolofmosaicart.com

Santa Barbara School of Mosaic Art was founded in 2009 by mosaic artist Tami Macala. Tami has over 15 years experience as a professional mosaic artist and shares her knowledge and expertise with every workshop. SBSMA is located in beautiful Santa Barbara, California, and hosts many talented artists from all over the world as guest instructors. SBSMA offers weekend workshops in a variety of mosaic art styles.

www.passifloramosaics.com

Since 2004 Fred and Donnell Pasion have taught hundreds of hands-on workshops, introducing thousands to mosaic art and concrete styrofoam sculpture. Whichever workshop you choose, you will discover why these weekend workshops held in their spacious studio have become so popular! Ideal for all skill levels from first-timers to seasoned hobbyists and professionals who want to refine their skills. Choose a project and you will be guided through the mosaic-making process from start to finish.

www.mosaicmorphosis.com

Karen Silton is a SAMA member at the Professional level and a professional ceramic tile and mosaic artist for 15 years. She offers high quality mosaic classes for children and adults from beginner through advanced levels in a very supportive environment. A large variety of materials including handmade ceramics, glass fusions, mirror, smalti, gold, vitreous glass and millefiori are available as well. Individual interests encouraged. Classes are small. Private instruction available also.

COLORADO

lilymosaics.com

Lily Russo is a mosaic artist with over 12 years experience. She offers beginner through advanced classes on stained glass and tile mosaics in Durango, Colorado and Tepoztlan, Mexico.

CONNECTICUT

www.bigbangmosaics.com

I teach the basics of the indirect method with vitreous glass. I love to teach and am eager to help others discover the pleasures of working in mosaic. Beginners to advanced, classes and one-on-one workshops. I teach at various art centers in New England, including the Worcester Art Museum, MA, Snow Farm Craft Center, MA, Brookfield Craft Center, CT and in my studio in Charlemont, MA.

FLORIDA

miyceramics.com

MIY Ceramics offers classes in mosaic, pottery, glass fusing, and painting. Craft parties and children’s classes are available.

www.beachlifemosaics.com

Mosaic artist Laure Norton offers a variety of instructional formats including private mosaic parties and children’s classes.

safetyharborartandmusiccenter.com

Create your own mosaic panel with mosaic artist Heather Richardson in this day-long workshop that will give a crash course to newbies and teach seasoned mosaic artists a few new tricks. All materials included, please bring safety glasses/goggles and rubber gloves. Private classes or private smaller group classes are available please contact Heather for more information [email protected] or call 727-424-2576

www.susannevernon.com

Susanne Vernon Mosaics offers project based mosaic classes for beginner, intermediate and advanced students. Projects vary as do material, so please check the classes page on our website for current workshops. Children’s classes and individual instruction are also available.

GEORGIA

www.callanwolde.org

This organization has offered mosaic classes in the past, and may still offer them from time to time.

www.spruillarts.org

This organization has offered mosaic classes in the past, and may still offer them from time to time.

ILLINOIS

www.chicagomosaicschool.com

Providing an arts education and fostering the creation of Mosaic Art using both ancient and contemporary techniques.

INDIANA

[email protected]

Teaches introductory mosaics workshops and offers workshops to create mosaic coasters and small frames at our location and local breweries in the area. Classes use a variety of glass tiles, millefiori and metallic shapes.

KENTUCKY

pammcglone.com

Pamela has multiple project-oriented classes available, including a stained glass mosaic window class, and a class for garden stepping stones. She can also schedule group project classes, such as team building exercises or classes for church groups.

LOUISIANA

www.truemosaics.com

Laurel True teaches mosaic classes for all levels at the New Orleans School of Art and Craft.

MASSACHUSETTS

www.cherylcohenmosaics.com

Cheryl Cohen Mosaics, for beginners and master artists alike, is a combination of great art, expert instruction and a fun and supportive community. Our 800+ square foot studio a mosaic artist’s dream, filled to the brim with plates to smash, stained glass to cut, and charms, beads, costume jewelry, shells, rocks and more, to create something small like coasters or picture frames for your home, or a one-of-a-kind masterpiece. Multiple weekly classes are available for adults and children.

www.bigbangmosaics.com

I teach the basics of the indirect method with vitreous glass. I love to teach and am eager to help others discover the pleasures of working in mosaic. Beginners to advanced, classes and one-on-one workshops. I teach at various art centers in New England, including the Worcester Art Museum, MA, Snow Farm Craft Center, MA, Brookfield Craft Center, CT and in my studio in Charlemont, MA.

carenzanefishman.com

Students learn about the process of creating mosaics; from the use of color and placement of tile to composition, and technical aspects of grouting and completing the piece. Students will learn while doing, through demonstrations and lots of hands on time.

betteannlibby.com

Bette Ann gives classes around 6 times a year with a focus on ceramic shard mosaics and sculpture. [email protected] 617-327-5171

www.mosaicoasis.com

On-going introductory classes (5 different sessions per week) that will prepare students to start their own project in a bright and cheerful studio. Also offers more involved workshops.

MICHIGAN

www.adambegleymosaics.com

This basic instructional workshop offers the beginner a solid foundation in the materials and methods necessary for doing traditional mosaic artwork. Please call or e-mail as we always arrange courses on a personal basis.

MINNESOTA

www.sheryltuorila.com

Small classes ensure a relaxed, fun, no pressure atmosphere for students to explore and develop their own individual creativity. A complete overview of mosaics including hands-on experience as students create one-of-a-kind custom wall panels. Explore the wide variety of mosaic materials in this class: ceramic tile, stained glass, china, and found objects. Introduction to adhesives, sources for materials and substrates. All materials included but students are encouraged to bring treasures of their own. Work outside of class may be necessary.

MISSOURI

Kansas City MO

www.KansasCityMosaics.com

3 Hour Basic Mosaics

This class is aimed at playing with the materials, learning the tools and adhesives. The first step in finding out that this is the most addictive art form ever.

Monthly 2nd and 4th Saturdays

MONTANA

www.pattyfranklinmosaics.com

Patty’s highly personalized style of instruction is a great beginning to learning the basics of making a direct method, stained glass, mosaic. You will learn about the wide variety of materials and where to purchase them, the various cutting tools and how to use them, which adhesive to use for what substrates, how to design a cartoon that will translate into a mosaic, the correct way to place the glass for a beautiful flow and, you’ll receive written directions for grouting (which color and how to mix, apply, and clean up). You’ll also get the all-important dos and don’ts that Patty has accumulated over a 15 – year career in contemporary mosaic arts. This is a relaxed, fun, no pressure, hands-on 3 hour session that allows you to explore a wonderfully meditative art form. Included in the fee are all of the materials needed to do a 10” by 10” mosaic design. (Students are encouraged to bring their own treasures.)

NEW JERSEY

www.designsbyeleanor.com

Eleanor teaches how to create a mosaic art classes for kids and adults in Towaco, New Jersey.

dunegrassmosaics.com

Accepts students at all levels, from beginner to advanced. All materials provided. Students learn the art of mosaics, how to design a project, how to cut and set tile, grouting and clean-up. Each student leaves with a beautiful finished product.

NEW MEXICO

www.mirafloresmosaics.com

Jill is a prolific mosaic artist. She has been teaching mosaic classes for many years, and has more classes coming up in 2023. Most of Jill’s classes are project-based, and she has a variety of project classes to choose from.

[email protected]

NEW YORK

www.mosaicmaster.com

Unicorn Art Studio, Inc. has been offering mosaics classes in New York City for over 15 years. Classes are for people of all ages, beginners and those with some experience. Variety of mosaic techniques are explored in full depth. A wide range of materials is available for use in class: glass, smalti, ceramic tiles, china, stone. You are welcome to visit the studio prior to signing up! No previous mosaic making experience is required in order to take a class!

www.newyorkartworld.com

Beginners and advanced students welcome. Workshops offered on Wednesday afternoons and evenings.

NORTH CAROLINA

www.lindapannullomosaics.com

Linda offers workshops with visiting mosaic artists of note in beautiful Ashville, NC.

OREGON

www.dennys-workshop.com

Denny offers beginning mosaic classes — including glass on glass, ceramic, and polymer clay. In addition, she periodicaly hosts special classes featuring guest instructors such as Kelley Knickerbocker and Christian Peres Gibaut. The studio sometimes offers open hours, as listed on the website.

PENNSYLVANIA

www.carolshelkinmosaics.com

A variety of mosaic techniques and materials are explored. Carol has been teaching art for over 25 years and has fine art professional training. She offers mosaic workshops, private lessons on all levels throughout the Philadelphia area and specialty workshops nationwide and worldwide including: Canada, Costa Rica, Australia and Mexico.

TEXAS

www.mosaicsbymichele.com

Monthly basic and intermediate classes offered. Wide range of materials used, students learn basic and intermediate design, setting, cutting, grouting techniques. Tools and material provided.

VERMONT

www.burlingtonglass.net

We offer a variety of stained glass design and mosaic design classses. Classes vary from 15 week 3 credit college level class to 3 hour workshops. Please call or e-mail for dates and times of upcoming classes 802-324-4019.

VIRGINIA

www.anitadamron.com

Anita is a prolific working artist showing at multiple galleries, and she offers mosaic classes at The Reston Community Center, The Art League School (Torpedo Factory) Madison Street Annex, and The Workhouse Art Center (Lorton).

During COVID-19 Anita has also added LIVE online classes to her offerings.

www.maverickmosaics.com

Maverick Mosaics specializes in unique learning experiences and creating beautiful art. Our educational focus is to Open Doors to your Creativity and help you Discover your Artistic Voice. We are dedicated to nurturing and expanding creative expression through the art and community of mosaic. Maverick Mosaics offers a variety of workshops and learning opportunities for all ages and skill levels, and we’re honored to host the region’s broadest schedule of acclaimed mosaic artists from around the world who share their talent and masterful techniques. We host art retreats and International travel adventures.

WASHINGTON

www.rivenworksmosaics.com

Kelley offers multilevel classes in glass mosaic, including her signature textured glass and stacked glass techniques. Kelley also offers one-on-one instruction tailored to specific interests, from design and cutting to architectural applications. Volunteers interested in gaining experience by assisting with commissions in the studio are welcome.

jkmosaic.com

Jennifer Kuhns has installed architectural mosaic throughout the U.S., for private, corporate and public clients. She also creates some portable artwork and garden mosaic, and she offers classes in techniques ranging from beginner to advanced levels. Jennifer’s specialties are precision glass scoring and techniques for mosaic installation, including exterior considerations.

Classes Outside the U.S.

ITALY

www.orsoni.com

Orsoni offers two-week thematic courses in micro-mosaic and portraiture as well as a Master in Mosaic course which is offered as either a 1 week, 2 week, or 3 day workshop. The Master course is accredited through the International Interior Design Association and a Master certificate is awarded to those who complete the 1 or 2 week course.

MEXICO

www.haciendamosaico.com

Shelby Glass Studio of California in conjunction with Hacienda Mosaico offers a weeklong workshop for beginners and intermediate levels in wonderful Puerto Vallarta, Mexico. This workshop includes highly personalized instruction in a non competitive, creative atmosphere. Included in the tuition are all materials, a beautiful room and breakfast and lunch prepared by our own chef. This year Shelby is offering a Mosaic Mask Workshop: A Mixed Media Event! Contact Shelby at [email protected] for more information.

www.ninadigiovanni.com

Offers 3-5 day workshops in contemporary, Byzantine, and Pre-Columbian mosaics. Nina is an award-winning mosaic artist and educator, Ravenna trained with over 20 years experience in contemporary and traditional mosaic. Classes are located in a beautiful historical artist’s paradise – San Miguel de Allende – a safe and welcoming place in the heart of Mexico.

NEW ZEALAND

www.waiohikiartsvillage.com

Artist Peter Smith teaches mosaic classes at the Waiohiki Art Centre in Hawkes Bay.

UNITED ARAB EMIRATES

Mosaic Art By Selina

Selina has been doing mosaic art over a decade and participated in various exhibitions in U.A.E.

UNITED KINGDOM

www.glitteringshards.com

Evening Workshops, weekday Mosaic Maker Drop-In’s and one-to-one classes in South London. weekly evening mosaic workshops in 7 week blocks. Each evening runs from 8-10pm at the studio of mosaic artist, Concetta Perot, in Tooting, London SW17. The course is suitable for all levels and small classes ensure lots of individual attention. During the course you can expect to make a small mosaic and gain knowledge about the variety of mosaic materials, tools, techniques, glues, suppliers, different mosaic methods and various do’s and don’ts. Concetta also runs Mosaic Maker Drop-In’s on Thursday mornings: you can come whenever you are able and take advantage of learning, resources and being exposed to the work of others for inspiration.

www.draw.org.uk

The class covers a brief history and styles of mosaics with step by step help planning and creating your mosaic art piece.

Natural undyed minerals, crystals, and stones for use in mixed-media mosaics with other found objects that are attached by pressing into

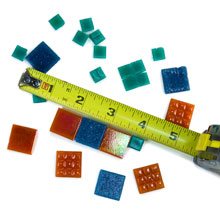

Natural undyed minerals, crystals, and stones for use in mixed-media mosaics with other found objects that are attached by pressing into  Small Polished Gemstones are natural undyed stone sold in 1/4 pound lots. There are approximately 40 to 60 pieces per 1/4 pound. Piece size ranges from approximately 1/2 to 3/4 inch. Gemstones have natural variation in their exact color, pattern, and shape. Do not order if that is a problem. Gemstones should be used as accents not area coverage. Coverage varies based on how the gemstones are nested and whether or not they are placed on end or flat.

Small Polished Gemstones are natural undyed stone sold in 1/4 pound lots. There are approximately 40 to 60 pieces per 1/4 pound. Piece size ranges from approximately 1/2 to 3/4 inch. Gemstones have natural variation in their exact color, pattern, and shape. Do not order if that is a problem. Gemstones should be used as accents not area coverage. Coverage varies based on how the gemstones are nested and whether or not they are placed on end or flat.