Mosaic wall art often takes the form of rectangular “plaques” which, visually, serve the same function as rectangular paintings on canvas. Paintings often look best when they have been framed properly; this can also be true for mosaics.

Paintings are usually framed with some kind of stained wood. This can be done for mosaic art as well, but this tutorial will show how to use another attractive option: angle aluminum. Aluminum might sound daunting at first, but with some common hand-tools a clean and sharp frame can be made for your mosaic. Aluminum is also nice because it doesn’t rust and the metallic shine nicely compliments glass.

Part I: Framing a mosaic that has not been grouted yet

Step 1: Preparation

Installing an aluminum frame is easiest when the mosaic has not yet been grouted. However, it is possible to put a frame onto an existing already-grouted mosaic using similar techniques. This tutorial will first demonstrate how to frame an un-grouted mosaic.

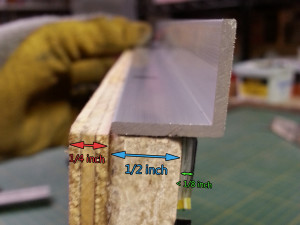

Angle aluminum is readily available in three sizes: 1/2 inch, 3/4 inch, and 1 inch. In my experience the 1/2 inch variety would be unsuitable for most of my artwork because it would be hard to get a screw into the side of it, and it wouldn’t provide a nice lip beyond the surface of the mosaic tile. 3/4 inch angle aluminum is big enough for most projects. Because of its size and weight, 1 inch angle aluminum is only suitable for mosaics whose base is at least 1/2 an inch thick, and should not be used for smaller projects.

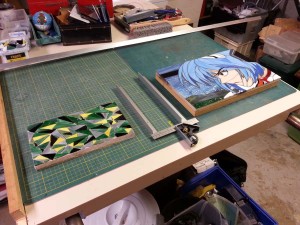

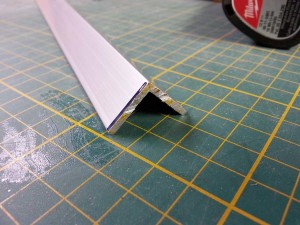

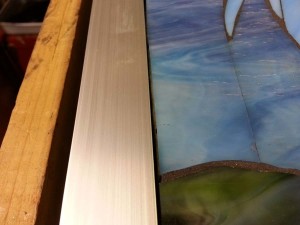

The first mosaic is an abstract pattern made of stained glass triangles glued with Weldbond onto a composite backer made of half-inch thick concrete backer board (CBB) and quarter-inch thick plywood. The total thickness of the backer is therefore 3/4 of an inch which is suitable for a 3/4 inch angle aluminum frame. The frame will need to sit a little higher than the glass, so the frame will rest solely on the CBB. The second mosaic is larger and will use a slightly different construction with 1 inch angle aluminum. We have a discussion about how to use concrete backer board as a mosaic surface on our page about ideal mosaic surfaces. Angle aluminum can be purchased in 8 foot lengths at your local big box hardware store. Don’t buy the cheap stuff, get one of the thicker materials seen in this tutorial. The dimensions can be seen more easily in this picture. Notice that each of the “arms” of the “L” are 1/16 inch thick.

The glue needs to be dried before you begin. If you used Weldbond you can perform most of the framing operations as early as three hours after gluing the last tile, but you should still wait 24 hours before grouting. This allows the glue to cure and develop water resistance so that it won’t be weakened by the wet grout.

Most of the tools used in this tutorial should already be available to you. You’ll want gloves, a hacksaw, a drill, a square, a ruler or measuring tape, screws, a metal file, and a marker. Safety glasses should also be worn while drilling. If you have a chopsaw in your garage or work room then you can use that instead of the hacksaw as long as you have a blade suitable for cutting metal. Aluminum is soft as far as metals go, so doing it by hand isn’t that difficult. You should wear gloves to protect your hands from the saw and from the metal file. A small slip with a file can actually take off quite a bit of skin so be careful.

Step 2: Measure the first piece

For this mosaic we will cut sections of angle aluminum at right angles and have two “inside” pieces butt up against two “outside” pieces. With a chop saw a mitred frame can be produced, but mosaic artists with only a hacksaw should stick to right-angle frames instead.

We will make one of the inside pieces first. When they’re completed it will be easy to make the outside pieces. Making the first inside piece is the hardest part of the project, so take your time and measure twice. Lay the aluminum flush with one edge of the mosaic, and then use a marker to draw the cutting line. When you cut bias the saw towards the outside of the mark because you’ll have to file it down.

Step 3: Make the first cut

When cutting with the hacksaw be sure to make many long but shallow strokes. Aluminum is tougher than wood, so you need to take it slow. It also helps if you clamp the aluminum to the table. Remember to leave some extra lenghth because you’re going to have to file the end later.

Step 4: Clean up the edge

After cutting the edge will be very sharp and dangerous. It must be filed down. Sandpaper is not ideal, it will get shredded by the aluminum and you risk scratching the surface that you want displayed. The marker can be wiped off now, but if it has set too long it might be dry. If that happens and water can’t get it off just hold the end of the bar in bleach for 15 seconds then wipe it on a rag.

Step 5: Measure in for screws

With our first piece cut we can now attach it to the frame, but the screws need to be positioned properly. Screw positioning depends on the dimensions of the angle aluminum and the thickness of the mosaic.

For this mosaic the screws will be put two inches in from each end, and then lined up so they go right into the middle of the CBB. It is better to have the screws go into wood than CBB, but for a small mosaic like this the CBB will suffice.

Step 6: Determine screw depth

We want the screws in the exact middle of the CBB so that they don’t damage it. With the angle positioned even with the CBB/plywood transition that means the screws are going to go 1/4 of an inch away from the lip of the angle aluminum. This gives us a nice gap above the surface of the glass.

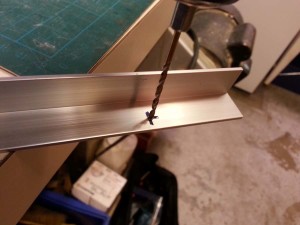

Step 7: Drill pilot holes

Mark the screw holes and clamp the bar of angle aluminum to the work surface. Drill pilot holes with a 1/32 drill bit before drilling out the actual hole size. The actual size is going to be determined by the type of screws you use.

Step 8: Drill the holes larger

Once the pilot holes have been drilled choose the appropriate drill bit and then drill the holes larger. Then check for burrs around the drill hole on both sides. They should be cleaned up before installing the frame piece.

Step 9: Attach the first piece

Line up the angle piece with the mosaic where you want it mounted. Drill through the holes into the CBB, but whatever the length of the screw is subtract about 1/4 inch. This doesn’t have to be exact. Screw the frame piece to the side of the mosaic.

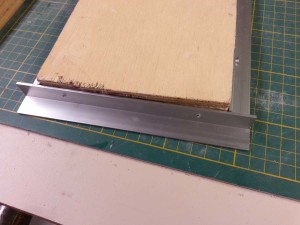

Step 10: Make the opposite piece

Repeat steps 2-9 to produce the next piece. Screw it on opposite the first piece, in the same manner as shown above. You can check for accurate fitment by taking the mosaic and resting it sideways on the table to see if your frame pieces line up properly, or you can use a square.

Everything needs to line up flush or else the next two pieces won’t fit properly. You can play with the angle at which the screws are drilled in and with tightening or loosening them to adjust the frame. This frame has two screws per side, but for larger pieces you might want to go with three screws. If you do that it can help to get the middle screw figured out before attaching the screws near the edge.

Step 11: Make one of the sides

Using steps 2-9 make one of the side pieces, but this time you need to allot enough extra length to accommodate the width of the two pieces you just installed. Now that the other two pieces are already in place you can flip the mosaic upside-down when you go to pre-drill the screw holes in the sides of the mosaic for the frame piece.

Step 12: Make the other side

With three pieces down, simply copy the piece you just made for the other side and install it. The frame is now complete.

Step 13: Fill in gaps if needed

If the mosaic backing was cut by hand (as this one was) there might be some small gaps between the frame and the mosaic. These gaps can be filled with Weldbond before grouting. If you do this wait 24 hours before grouting so the glue can dry. I glued the seam and then pressed the glue in with my index finger, wiping the excess onto a paper towel.

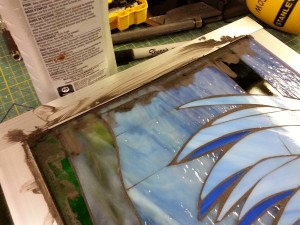

Step 14: Grout your mosaic

The final step for the frame is to grout the mosaic. If the frame is installed before grouting it saves lots of trouble later.

The grout I use in this tutorial dried rather quickly because it was done in a warm environment, but exposure to wet grout can stain some aluminum trim pieces because of a mild chemical reaction. It’s best to mask the surface of the frame to prevent contact with wet grout.

You’re Done!

At this point the frame is complete and the mosaic is grouted. All that remains is to put a hanging wire or hook on the back and sign it.

Part II: Framing a mosaic that already has grout

Framing a mosaic which has already been grouted with an angle aluminum frame is not ideal!! You should try to decide whether or not a mosaic will get a frame before you grout it, or you should look at using some kind of trim wood with a lip to make a mitred frame which covers the edges of the mosaic.

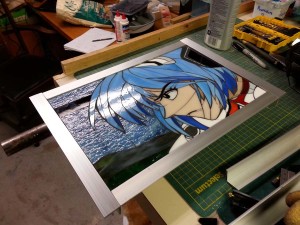

That being said, you may find yourself in the position I found myself in when I decided to make this tutorial. I had a mosaic I was very proud of, but after grouting it I realized that the way I had planned to deal with the edges just wasn’t going to look as nice as I wanted it to. I could tell that this piece needed a nice clean frame and I had to do it even though the grout was already in place.

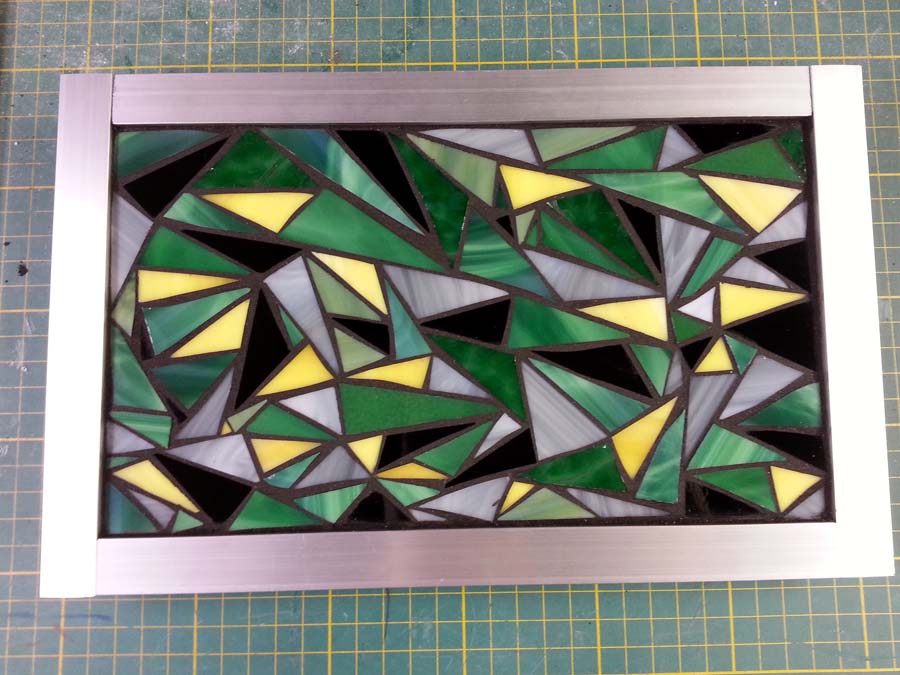

Part II shows how to install a frame made out of 1 inch angle aluminum onto a stained glass mosaic whose backing is a little over 1 inch thick. You will follow the same steps as Part I, but make accommodations for the larger size of the mosaic, the new size of aluminum, and the deeper thickness of the mosaic backing.

Building the Frame

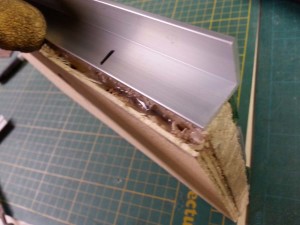

This mosaic is mounted on 1/2 inch concrete backer board as was the previous mosaic, but this time the wood backing is much thicker. Between the wood and the larger aluminum we are able to screw directly into the side of the wood.

You can see in the diagram that the aluminum overlaps the wood by about 5/16 of an inch, yet still has a nice lip above the glass. We’re putting the screws about mid-way through this overlap directly into the wood, or about 5/32 of an inch from the edge of the aluminum. The piece is also larger so you may notice that there are three screws each on the top and bottom. I installed the middle screws first.

Grout the seams

Once the frame is constructed you might find that there are gaps along the edges. These gaps can be filled with grout. Mix a small amount of it and try to work only around the areas that need it. You might find that one side is already flush with the frame and doesn’t need any grout. Be sure to clean out the grout properly so that it lays flush with the grout on the mosaic so it looks nice.

All Finished!

Once again your mosaic is essentially complete and all you need to do is put some mounting hardware on the back. Enjoy your new mosaic.